Fragmented stocktake processes lead to errors, shrinkage and operational downtime. Optilogix delivers an end-to-end stocktake solution integrating barcode/RFID scanning, real-time data capture and seamless ERP integration. Gain full visibility, audit accuracy and streamline stock counts across all stores, warehouses and locations with live dashboards, variance reports and mobile scanning tools built for speed and reliability.

Fragmented stocktake processes lead to errors, shrinkage and operational downtime. Optilogix delivers an end-to-end stocktake solution integrating barcode/RFID scanning, real-time data capture and seamless ERP integration. Gain full visibility, audit accuracy and streamline stock counts across all stores, warehouses and locations with live dashboards, variance reports and mobile scanning tools built for speed and reliability.

Stocktake Solution

Powerful & Easy

Hardware & Reporting Only

- Hardware Application Included

- Remote Training & Support

- Client Provides Staff

- Reports as Required

Fast & Efficient

Hardware, Reporting & Trainer

- Hardware Application Included

- Trainer Provided

- Client Provides Staff

- Reports as Required

Ground Breaking

Fully Managed Stocktake

- Hardware & Application Included

- Project Manager Provided

- Staff Provides

- Reports as Required

Stocktake Solution

Powerful & Easy

Hardware & Reporting Only

- Hardware Application Included

- Remote Training & Support

- Client Provides Staff

- Reports as Required

Fast & Efficient

Hardware, Reporting & Trainer

- Hardware Application Included

- Trainer Provided

- Client Provides Staff

- Reports as Required

Ground Breaking

Fully Managed Stocktake

- Hardware Application Included

- Project Manager Provided

- Staff Provides

- Reports as Required

Functionality

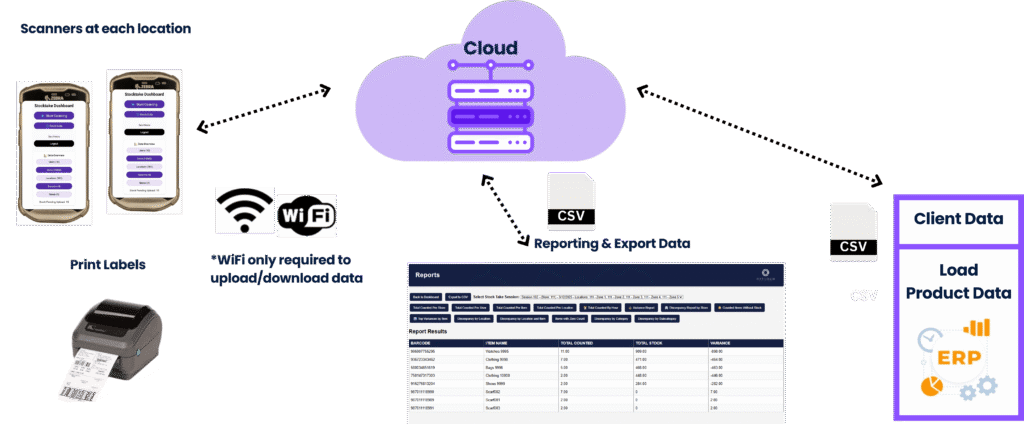

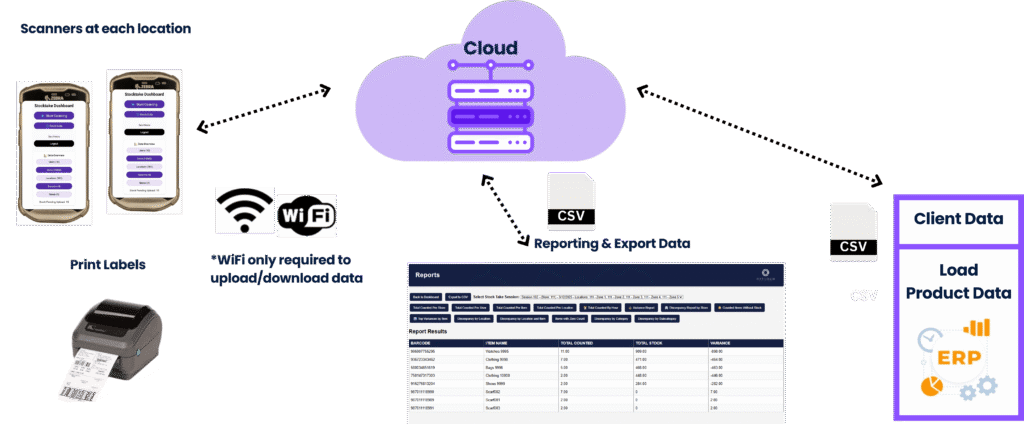

Our stocktake process is powered by a secure, cloud-based platform hosted on AWS ensuring scalability, real-time access, and smooth execution across locations.

Devices scan data on-site, which syncs to the cloud via WiFi, then feeds into custom reporting dashboards like PowerBi. Reports are exported in client-preferred formats (CSV, XML) and integrated with your ERP or inventory system.

Label printing and data management are remotely supported via AnyDesk, keeping your infrastructure light and hassle-free.

Functionality

Our stocktake process is powered by a secure, cloud-based platform hosted on Microsoft Azure — ensuring scalability, real-time access, and smooth execution across locations.

Devices scan data on-site, which syncs to the cloud via WiFi, then feeds into custom reporting dashboards like Qlik Sense. Reports are exported in client-preferred formats (CSV, XML) and integrated with your ERP or inventory system.

Label printing and data management are remotely supported via AnyDesk, keeping your infrastructure light and hassle-free.

Stocktake Preparation

It is important to plan out the process before starting a stocktake carefully.

PLAN REQUIRED

- The best time to conduct the stocktake

- The number of staff required

- The stocktake software & equipment needed

ORGANISE YOUR INVENTORY

Making sure that items are properly labelled and stored in their correct locations. Two common issues before stocktaking are:

- No barcodes on products

We provide barcode labels for shelves, or, for product packaging allowing accurate product identification through scanning barcodes. - No barcodes in the organizations catalogue.

Catalogues and ERPs often lack barcode data or support only one barcode per SKU. Our system captures unrecorded barcodes during audits and live stocktakes to build a complete, accurate catalogue.

Stocktake Preparation

It is important to plan out the process before starting a stocktake carefully.

PLAN REQUIRED

- The best time to conduct the stocktake

- The number of staff required

- The stocktake software & equipment needed

ORGANISE YOUR INVENTORY

Making sure that items are properly labelled and stored in their correct locations. Two common issues before stocktaking are:

- No barcodes on products

We provide barcode labels for shelves or for product packaging allowing accurate product identification through scanning barcodes. - No barcodes in the organizations catalogue.

Catalogues and ERPs often lack barcode data or support only one barcode per SKU. Our system captures unrecorded barcodes during audits and live stocktakes to build a complete, accurate catalogue.

How the system works

How the system works

Step 1

Planning & Scope Alignment

We begin with a discovery call to assess your stock environment, locations, and timeline. Scope and labelling strategies are finalized upfront.

Step 2

Hardware Setup & Tagging

We provide and configure all required hardware. Products are tagged or verified to ensure they’re ready for accurate scanning.

Step 3

Execution

Based on your chosen model, our certified team or your trained staff conducts the count with speed and minimal disruption.

Step 4

Reporting & Insights

Detailed reports highlight stock variances, risk areas, and recommendations. Formats are tailored to your ERP or reporting platform.

Step 1

Planning & Scope Alignment

We begin with a discovery call to assess your stock environment, locations, and timeline. Scope and labelling strategies are finalized upfront.

Step 2

Hardware Setup & Tagging

We provide and configure all required hardware. Products are tagged or verified to ensure they’re ready for accurate scanning.

Step 3

Execution

Based on your chosen model, our certified team or your trained staff conducts the count with speed and minimal disruption.

Step 4

Reporting & Insights

Detailed reports highlight stock variances, risk areas, and recommendations. Formats are tailored to your ERP or reporting platform.

Step 1

Planning & Scope Alignment

We begin with a discovery call to assess your stock environment, locations, and timeline. Scope and labelling strategies are finalized upfront.

Step 2

Hardware Setup & Tagging

We provide and configure all required hardware. Products are tagged or verified to ensure they’re ready for accurate scanning.

Step 3

Execution

Based on your chosen model, our certified team or your trained staff conducts the count with speed and minimal disruption.

Step 4

Reporting & Insights

Detailed reports highlight stock variances, risk areas, and recommendations. Formats are tailored to your ERP or reporting platform.